1100 Aluminum foil

Heat treatment can not be strengthened; Low strength, but good ductility, formability, weldability and corrosion resistance;

After anodic oxidation, the corrosion resistance can be further improved and a beautiful surface can be obtained.

Classification :

Aluminum Foil

Key Words:

Aluminum Foil

About the aluminum

1100 aluminum alloy is 99.0% ordinary industrial pure aluminum. Heat treatment can not be strengthened; Low strength, but good ductility, formability, weldability and corrosion resistance; After anodic oxidation, the corrosion resistance can be further improved and a beautiful surface can be obtained. 1100 aluminum alloy is formed by adding a small amount of copper element in pure aluminum, with excellent forming characteristics, high corrosion resistance, good weldability and electrical conductivity. Widely used in products requiring good formability and high corrosion resistance, but not high strength requirements.

Aluminum is a silver-white light metal, relatively soft, density 2.7g/cm3, melting point 660.4℃, boiling point 2467℃, aluminum and aluminum alloys have many excellent physical properties, has been very widely used. Aluminum has good reflection performance of light, reflecting ultraviolet light is stronger than silver, the purer aluminum is, its reflection ability is better, and the method of vacuum aluminum plating is commonly used to make high-quality mirrors. Vacuum aluminized film combined with polysilicon film becomes a cheap and lightweight solar cell material. Aluminum powder can maintain a silvery luster, often used to make paint, commonly known as silver powder. Pure aluminum conducts electricity very well, second only to silver and copper. In the electric power industry, it can replace part of copper for wires and cables. Aluminum is a good conductor of heat. It can be used to make various heat exchangers, heat dissipating materials and civil cookers in industry. Aluminum has good ductility, can be drawn into a fine wire, rolled into a variety of aluminum products, but also can be made into thinner than 0.01mm aluminum foil, widely used in packaging cigarettes, candy, etc.. Aluminum alloy has some better properties than pure aluminum, which greatly expands the application range of aluminum. For example, pure aluminum is soft, when a certain amount of copper, magnesium, manganese and other metals are added to aluminum, the strength can be greatly improved, almost equivalent to steel, and the density is small, not easy to rust, widely used in aircraft, cars, trains, ships, artificial satellites, rockets manufacturing. At -196 ° C, some steel is as brittle as glass, while some aluminum alloys increase in strength and toughness, making them cheap and lightweight cryogenic materials that can be used to store liquid oxygen and hydrogen for rocket fuel.

PRODUCT

| Standard | ASTM GB JIS AISI,EN |

| Thickness | 0.006mm(6micron) - 0.2mm (200micron) |

| Width | 120- 1500 mm (tolerance:± 1.0mm) |

| Temper | O,F, H12, 114,H18,H22, H24,H26,H32, etc |

| Application | Aluminum foil is widely used in food, beverage, cigarette, medicine, photographic plate, household articles, etc. It is usually used as its packaging material, electrolytic capacitor materials, insulation materials for buildings, vehicles, ships and houses. |

| Price Term | Ex-work, FOB, CFR, CIF, etc |

| Delivery Time | 20-30 days. Standard size is in stock,prompt delivery or as order's quantity. |

| Package | Export standard package, Carton box or wooden case, or waterproof paper, or as customer's request. |

| The inner size of container is below: | |

| 20ft GP: 5.9m(length) x 2.13m(width) x 2.18m(high)about 24-26CBM | |

| 40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM |

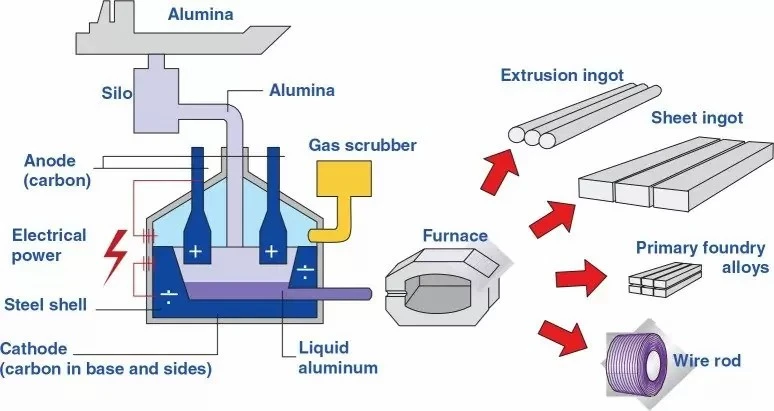

Aluminum Production Process

Packing and delivery

The company has main production lines such as pickling, cold rolling, hot-dip galvanizing, hot-dip galvanizing, thick plate galvanizing, and color coating, forming an annual output of 1 million tons of pickling coils, 1 million tons of cold-rolled steel sheets, and 900,000 tons of hot-dip steel sheets. The scale of galvanized and hot-dip aluminum-zinc-silicon steel sheets, 450,000 tons of thick galvanized steel sheets, and 300,000 tons of color-coated steel sheets. It is one of the largest suppliers of steel and non-ferrous metal smelting and processing in Shandong Province.

Factory

The company has main production lines such as pickling, cold rolling, hot-dip galvanizing, hot-dip galvanizing, thick plate galvanizing, and color coating, forming an annual output of 1 million tons of pickling coils, 1 million tons of cold-rolled steel sheets, and 900,000 tons of hot-dip steel sheets. The scale of galvanized and hot-dip aluminum-zinc-silicon steel sheets, 450,000 tons of thick galvanized steel sheets, and 300,000 tons of color-coated steel sheets. It is one of the largest suppliers of steel and non-ferrous metal smelting and processing in Shandong Province.

Customer visit

Shandong Huaxin Steel Trading Co., Ltd. is a comprehensive large-scale enterprise integrating coating products and various steel processing and production, warehousing, distribution, and foreign trade sales. It is also a national leader in high-strength ultra-thin steel plates. It belongs to the provincial and municipal key export enterprises.

APPLICATION AREAS

It is often used to build infrastructure such as skyscrapers, bridges and stadiums. Its high strength and durability make it a preferred material for supporting heavy loads and withstanding severe weather conditions. In addition, it is widely used in vehicle and machinery manufacturing. From cars and trucks to trains and ships, it is essential to ensure the reliability and safety of transportation systems.

WHY CHOOSE US

The company has main production lines such as pickling, cold rolling, hot-dip galvanizing, hot-dip galvanizing, thick plate galvanizing, and color coating, forming an annual output of 1 million tons of pickling coils, 1 million tons of cold-rolled steel sheets, and 900,000 tons of hot-dip steel sheets.

Enterprise mission

to make products, to serve customers, to benefit employees, and to contribute to society

Enterprise Vision

Win-win Cooperation.

Enterprise tenet

quality as life, customer as the center, employees as the fundamental, innovation as the driving force, integrity as the principle

Enterprise spirit

proactive and unremitting

RELATED PRODUCTS

GET A FREE QUOTE